Productbeschrijving

Na twee jaar van intensieve technologische innovatie heeft de Huashida PERT geïsoleerde pijplijnproductie met succes 130 onderzoeks- en ontwikkelingsproblemen aangepakt.tot vaststelling van een volledig onafhankelijke, uitgebreide oplossing voor intellectuele-eigendomsrechtenDoor gebruik te maken van nauwkeurig ontworpen extruder schroeven en vaten, geavanceerde pijpleiding en optimaal ontworpen koelsystemen,Deze productielijn zorgt voor de productie van PERT-geïsoleerde buizen van hoge kwaliteit.De prestaties en betrouwbaarheid zijn nu erkend als internationaal toonaangevend.

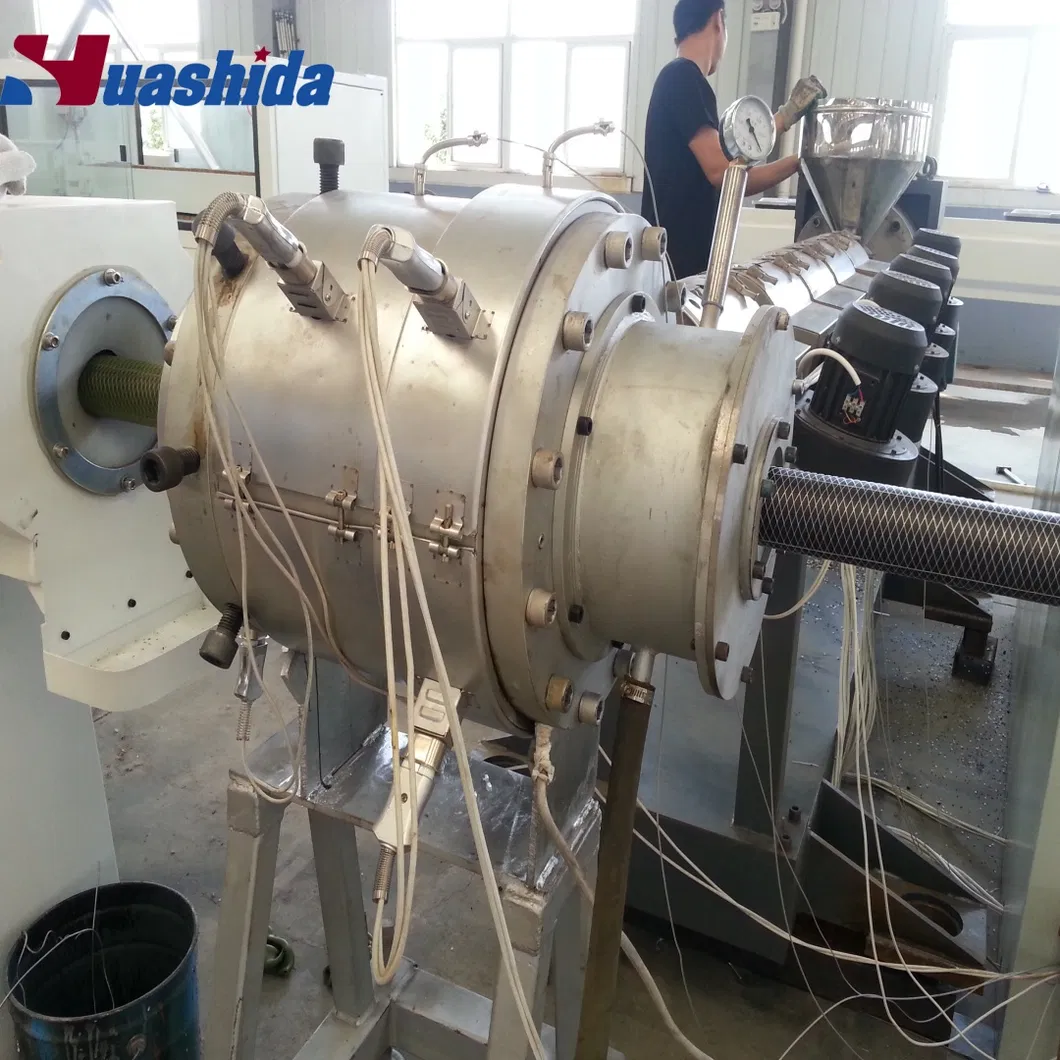

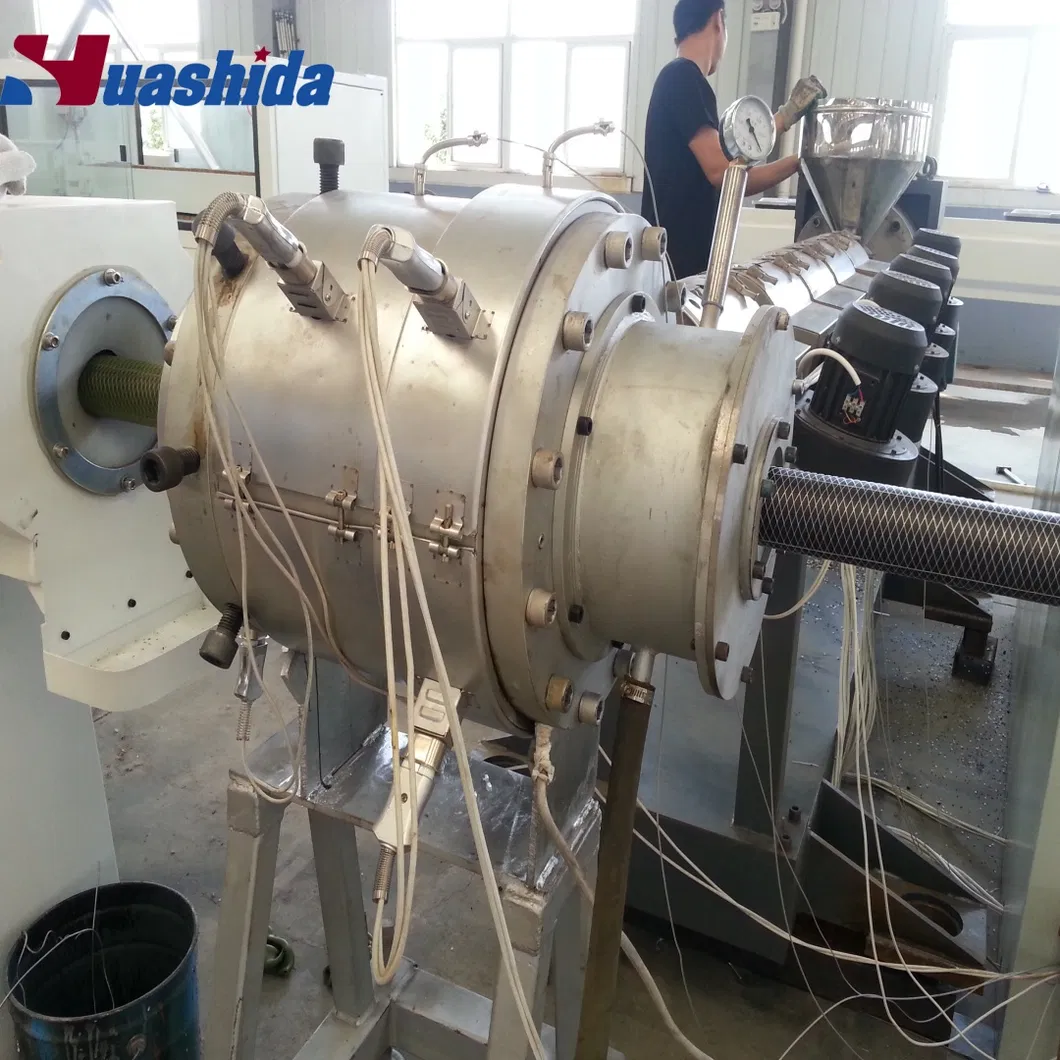

Het kenmerk van deze productielijn is dat het gietproces van polyurethaan schuim continu verloopt.De binnenpijp wordt samen met het polyurethaan schuimmengsel continu in het gietgebied geleid, vervolgens bekleed en gevormd met een film, en vervolgens door een ronde matrijskop gehaald om te worden bekleed met de buitenste beschermlaag die door de extruder wordt geextrudeerd.

Kenmerken

Dit type buis is een nieuwe generatie PU-isolatiepijp, met vele voordelen, zoals licht, gemakkelijk te bedienen, weinig gewrichten en goede flexibiliteit.

Het wordt hoofdzakelijk gebruikt om warmte van het hoofdleidingsysteem naar woningen of gebouwen te vervoeren.√Isolatie:

De thermische geleidbaarheid is zo laag als 0.013De 92% gesloten-cel snelheid zorgt voor een levensduur van meer dan 50 jaar.√Anti-corrosie eigenschappen:

De schuimlaag is nauw verbonden, waardoor luchtvochtigheid wordt geïsoleerd en langdurige duurzaamheid in harde omgevingen wordt gewaarborgd.√Economische sector:

Bespaar 50% van de opgravingskosten en 90% van de civiele bouwkosten, verkorte de bouwperiode met de helft en gebruik intelligente besturing om het energieverbruik te verminderen.√Milieuvriendelijkheid:

Minder landgebruik, nul afval in de productie en groene processen zijn duurzamer.

Productparameters

| Model |

Dia.Range |

Extruder |

Kracht |

Capaciteit |

| PERT-110 |

20 tot 110 |

60/33 |

150 kW |

180 kg |

| PERT-250 |

75 tot 250 |

75/35 |

220 kW |

250 kg |

| PERT-250 |

160 tot en met 350 |

90/33 |

260 kW |

500 kg |

Onze voordelen

Marktleiderschap:

Vertrouwd door meer dan 400 binnenlandse bedrijven met een terugkooppercentage van 70%.

Hoge prestaties:

Een hoge snelheid, stabiele en betrouwbare productie met een ongeëvenaarde efficiëntie.

Wereldwijd bereik:

Exporteerd naar Europa, Amerika, het Midden-Oosten, Centraal-Azië, Afrika en Rusland.

Reactieve ondersteuning:

24/7 service-responsmechanisme voor binnenlandse en internationale klanten.

Bewezen betrouwbaarheid:

Een betrouwbaar merk, erkend voor kwaliteit en innovatie in de productie van isolatiebuizen.

Productielijn Details

Equipmentcomponenten:

-- Productielijn voor binnendrukbuizen (PERT, PEX)

-- Inwendige buisontwikkelingsinrichting

-- Pijpvoedingsapparaat

-- Transportband

-- Centersysteem voor de buis

-- Voorverwarming en temperatuurregeling

-- Filmvoedingstoestel

-- Hoogprecisie-schuimmachine

-- Met temperatuurregeling gevormd

-- Extruder voor het omhulsel van buizen en waterkoeling

-- Aftrekapparaat

-- Wikkelmachines

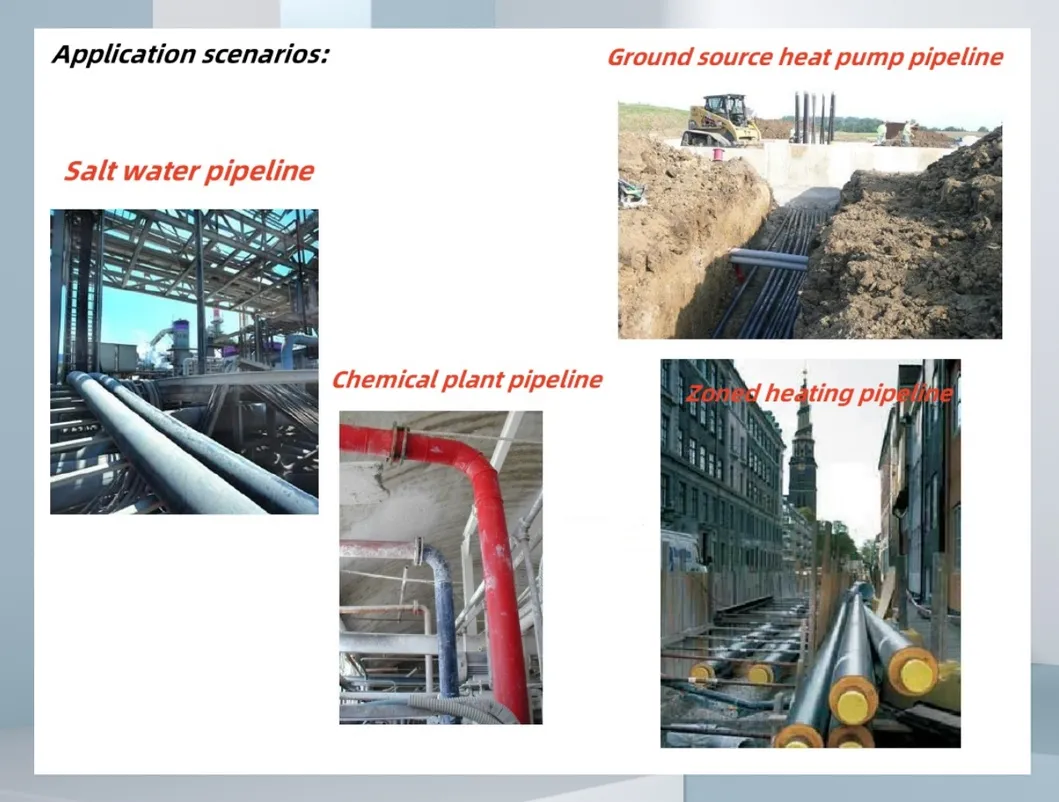

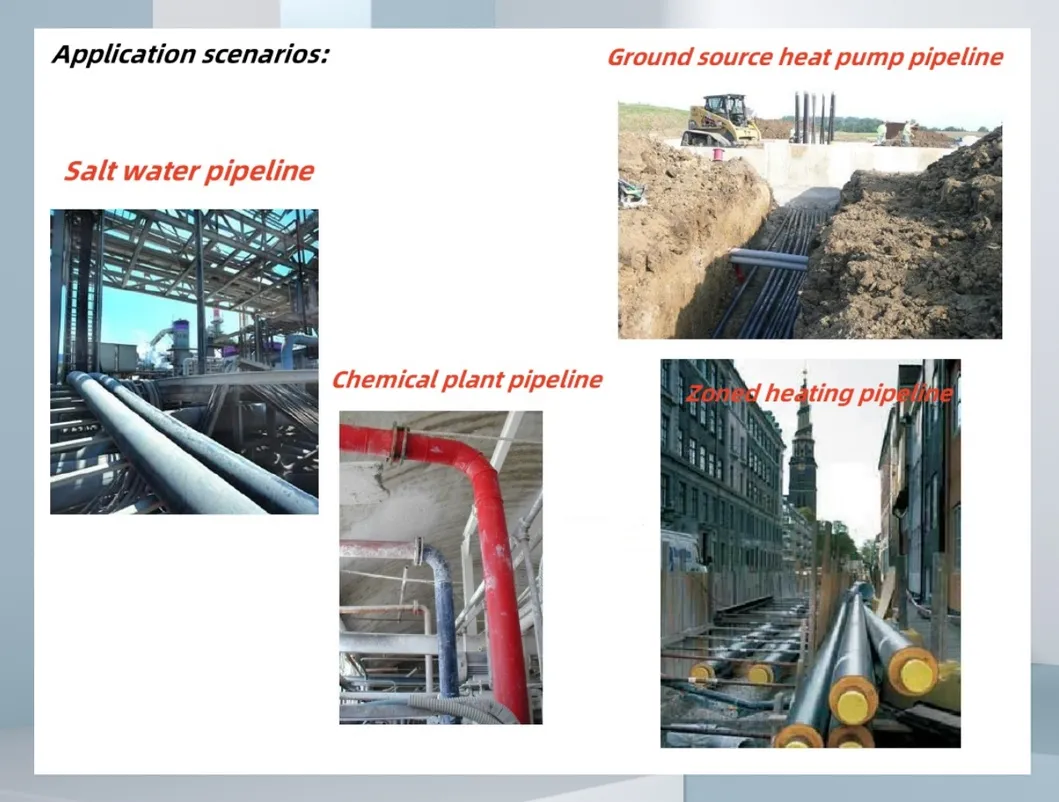

Productie-toepassingen

Huashida's cOncontinue PERT-geïsoleerde buisDeze leidingen zijn ideaal voor een breed scala van toepassingen, waaronder stadsverwarming, koelsystemen, olie- en gasleidingen en industriële leidingen.Het is de meest gebruikte methode voor het opstellen van een ontwerp., duurzame leidingsystemen.

Klantenzaken

Profiel van het bedrijf

Qingdao Huashida Machinery Co., LTD is een fabrikant vanPlastic-pijpmachines, gemeentelijke pijpmachines, pijpenisolatie- en corrosie-machines, enverbinding van buizen&anti-corrosie materialen,met 21 jaar productie ervaring.

Onze belangrijkste producten zijn:

1. HDPE jaspijp voor voorgeïsoleerde pijp Productielijn

2Productielijn voor stijve voorgeïsoleerde buizen

3. Productielijn voor flexibele voorgeïsoleerde buizen ((PERT))

4. staalpijp FBE/2LPE/3LPE anti-corrosie coating line

5. Lijn voor het ontlasten van stalen buizen

6. Productielijn van PE-drukbuis/watergastoevoerbuis

6Productielijn voor PP/PE-platen/platen/geomembranen

7NBR PVC productielijn voor thermische isolatiebuizen/platen

8.Anticorrosiematerialen en -instrumenten voor pijpleidingen: warmtebestendige bekleding van de verbinding, elektrische fusie-sweisbare verbinding, draagbaar laspistool ((extruder), PE PP-sweisstaaf.

We werken met meer dan 400 buitenlandse klanten en exporteren onze producten naar Kazachstan, Oezbekistan, Iran, Turkije, Rusland, Nigeria en andere landen.

Fabrieksoverzicht

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!