HDPE Pijp Productie Apparatuur voor Gemeentelijk Water /Aardgas / Energie Pijpleiding Systemen

Deze productielijn is speciaal ontworpen voor de productie van hoogwaardige PE80/PE100 pijpen, variërend van Ø20mm tot Ø2000mm. Het is een ideale keuze voor toepassingen zoals gemeentelijke watervoorziening, agrarische irrigatie, stedelijke gastransport en industriële pijpleidingnetwerken. Door de integratie van geavanceerde extrusietechnologie, efficiënte enkelschroefsextruders en intelligente besturingssystemen, garandeert het hoge precisie, uitstekende duurzaamheid en stabiele werking in de pijpproductie.

Technische specificatie

| Model |

Pijpdiameter |

Schroef |

KiloWatt |

Output |

| SPEG-110 |

20-110mm |

SJ75X33 |

180kw |

350kg/u |

| SPEG-250 |

63-250mm |

SJ90X33 |

280kw |

500-1000kg/u |

| SPEG-630 |

315-630mm |

SJ120X33 |

522kw |

1000-1200kg/u |

| SPEG-1200 |

710-1200mm |

SJ150X33 |

680kw |

1000-1600kg/u |

| SPEG-2200 |

1000-2200mm |

SJ150X33 |

1200kw |

2000-2500kg/u |

Toepassingen

- Gemeentelijke waterdistributienetwerken

- Aardgastransportleidingen

- Geothermische verwarmingssystemen

- Pijpen voor het verzamelen van afvalwater van stortplaatsen

- Industriële chemische transport

- Agrarische irrigatiesystemen

Technologische processen

[Voeden&Drogen] → [Extrusie Vormen] → [Vormen in de Mal] → [Koelen] → [Tractie en Snijden] → [Markeren]

Lijst met hoofdapparatuur

-1set Vacuüm lader

-1set Trechterdroger

-1set Hoogrendement enkelschroefsextruder

-1set 25/25 enkelschroefsextruder voor markeerlijn

-1set Vacuüm kalibratietafel

-2/4 set Watersproeitank

-1set Trekmachine

-1set Snijmachine

-1set Stapelaar

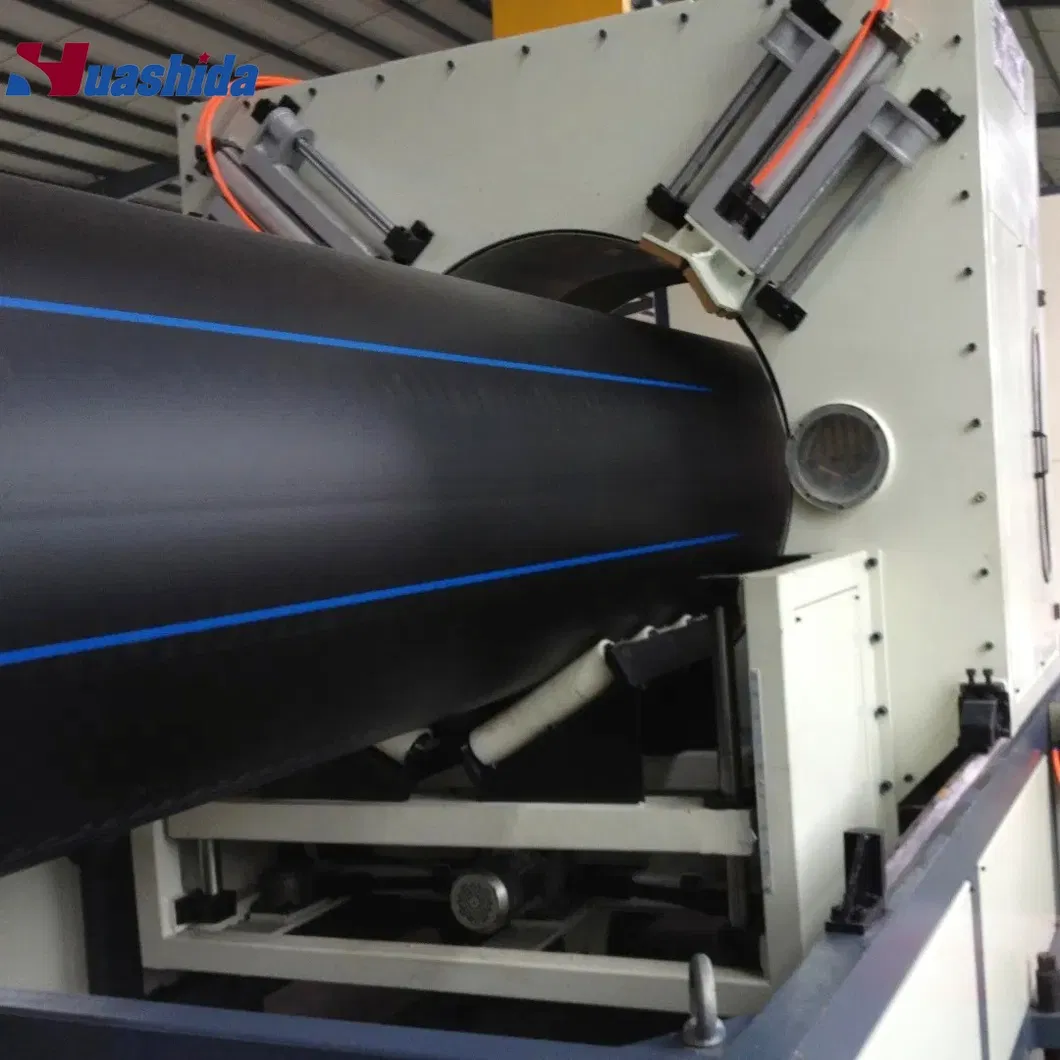

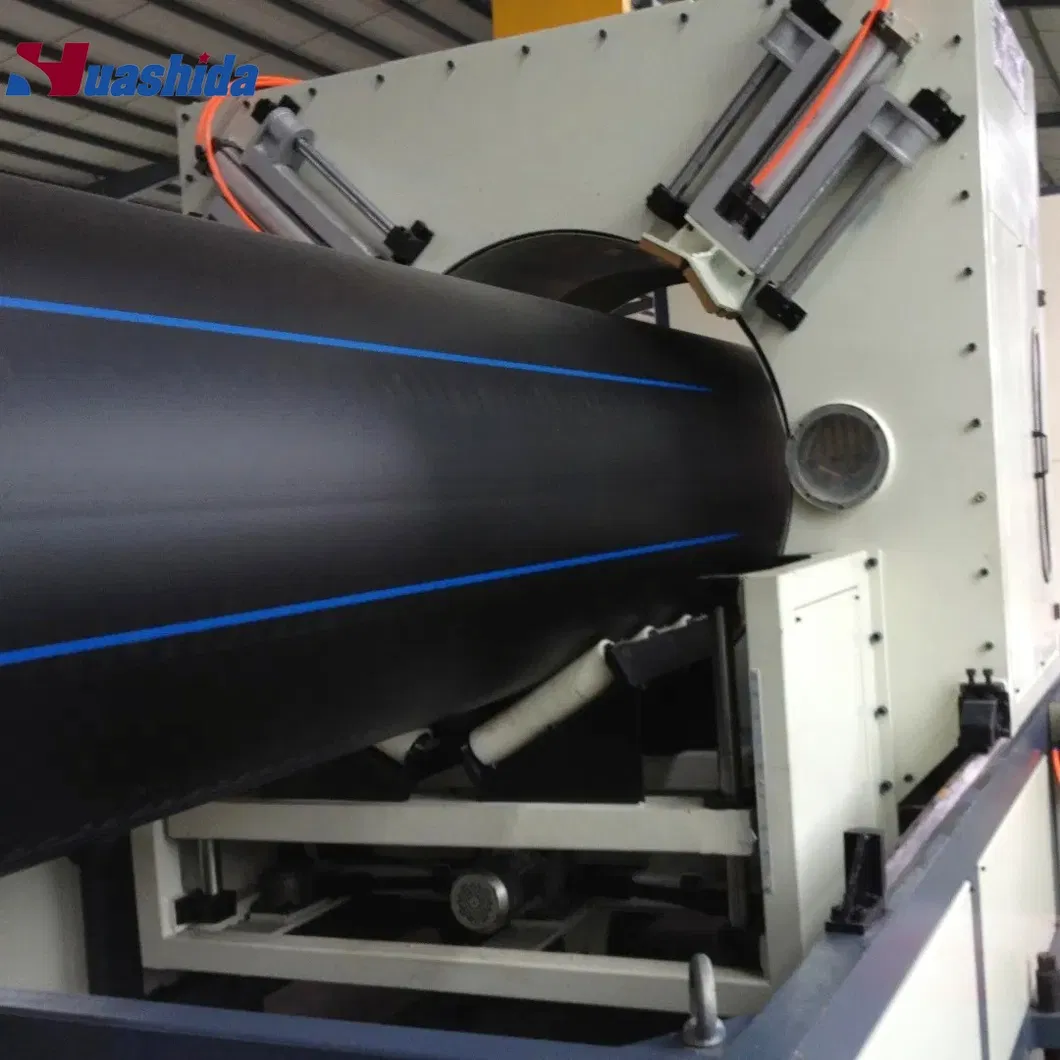

Detail foto's

√ Hoogrendement extruders bieden krachtige plasticiseercapaciteit en stabiliteit.

√ De spiraalvormige kop heeft een lage werktemperatuur, lage druk en een goede menging.

√ Watersmering en waterringkoeling zorgen voor de stabiliteit van de rondheid van de pijpdiameter.

√ De gehele productielijn wordt bestuurd door PLC en parameters kunnen worden ingesteld en weergegeven op het touchscreen.

√ Technologieën zoals meerlaagse co-extrusie verminderen de productiekosten aanzienlijk.

- Zorg voor stabiele operationele prestaties.

- Bereik een hoge mate van automatisering, waardoor de arbeidskosten worden verlaagd.

- Lever kwaliteit die voldoet aan internationale normen.

- Bied complete turnkey productoplossingen: ontwerp, installatie, inbedrijfstelling, training.

- Maak gebruik van 389 wereldwijde productieproject ervaringen.

- Maak gebruik van 9 senior professionele ingenieurs.

- Beheer een toonaangevend R&D-centrum voor plastic machines in China.

Qingdao Huashida Machinery Co., LTD, is een fabrikant van series van plastic pijp machines, gemeentelijke pijpmachines, pijp isolatie&anticorrosie machines, en pijpverbinding&anticorrosie materialen, met 21 jaar productie-ervaring.

Onze belangrijkste producten zijn:

1. HDPE mantelbuis voor voorgeïsoleerde pijp Productielijn (110-2000mm)

2. Stijve voorgeïsoleerde pijp Productielijn

3. Flexibele voorgeïsoleerde pijp(PERT) productielijn

4. Stalen pijp FBE/2LPE/3LPE anti-corrosie coatinglijn

5. Stalen pijp ontroestingslijn

6. PE druk pijp/Water Gas toevoer pijp productielijn

6. PP/PE plastic plaat/folie/geomembraan productielijn

7. NBR PVC Thermal isolatie buis/plaat productielijn

8. Pijpleiding anti-corrosie materialen en instrumenten: warmtekrimpverbinding coating huls, elektro-fusie lasbare verbindingshuls, draagbare laspistool (extruder), PE PP lasstaaf.

We werken samen met meer dan 400 buitenlandse klanten en exporteren onze producten naar Kazachstan, Oezbekistan, Iran, Turkije, Rusland, Nigeria en andere landen.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!